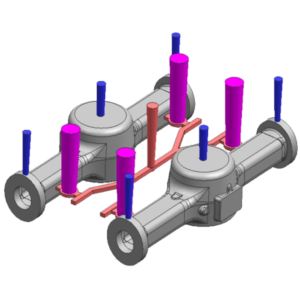

Discover V-Process Casting (VPC) that employs a special EVA Film to create moulds without binders, ensuring precise dimensions and effortless mould release. A standout feature of VPC is its near-total sand recovery, slashing material costs by 15-20% compared to traditional casting methods.

VPC is a revolutionary Japanese innovation now reshaping India’s foundry landscape. V-process excels in producing castings with impeccable surface quality and minimal defects, courtesy of its unique vacuum moulding technology.