The Lost Foam Shell Process combines precision foam patterns, refractory shell coating, and vacuum-assisted sand compaction to produce small and large, high-quality castings reliably.

Consequently, foundries can achieve superior surface finish, minimal machining, and high metallurgical integrity. Moreover, this method handles stainless, low-alloy and duplex steels – even castings from 500 grams to 2 tons and above – while reducing waste and lowering costs significantly.

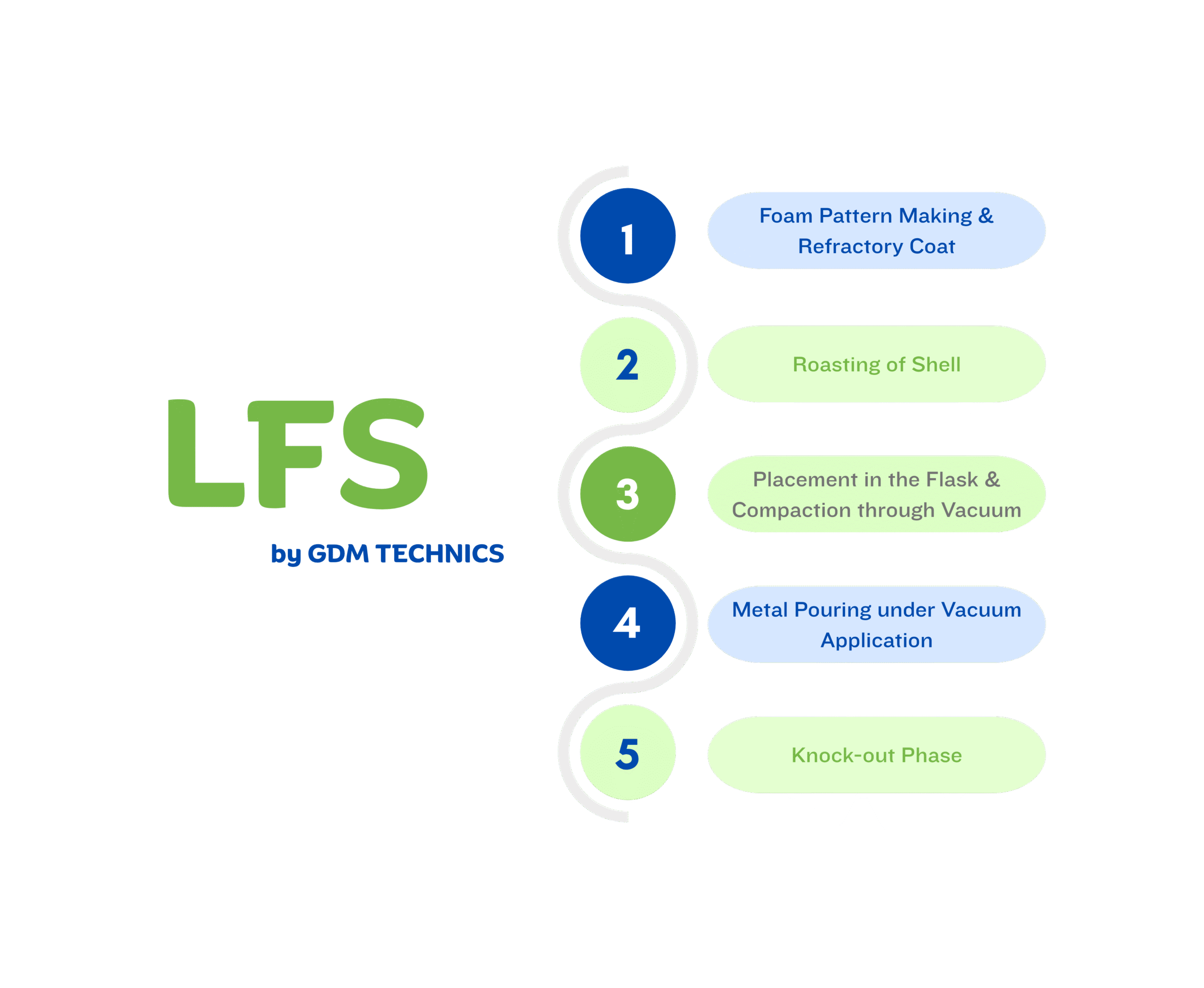

Briefly, the Lost Foam Shell Process (LFS) forms a refractory shell by applying multiple coating layers over an EPS foam model. After coating, we roast the foam in an electrical gasifier or baking furnace, allowing the foam to vaporize and leave behind a precise hollow shell. We then pour molten metal directly into this shell.

This hybrid of Lost Foam Casting (LFC) and shell technology allows foundries to manufacture large, complex geometries with accuracy as compared to traditional Lost-Wax precision casting.

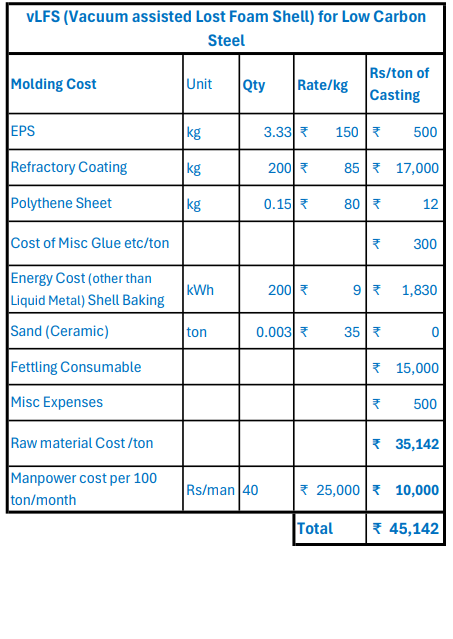

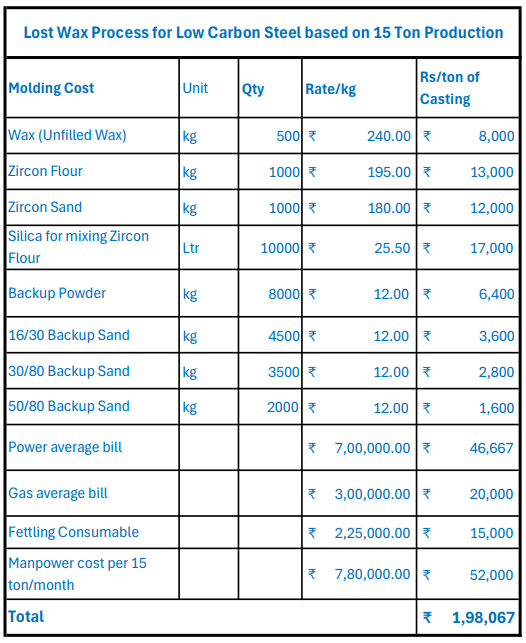

Therefore, foundries currently using Lost Wax Casting for components over 500 grams can adopt the Lost Foam Shell Process (LFS) to maintain precision and surface finish, while lowering overall operational costs by nearly 77%.

• Cost and Waste Efficiency: Reusable dry sand, ZERO CORE requirements, and streamlined process steps significantly reduce overall production costs.

• Wide Casting Range: Produce castings from 500 grams up to 2000+ kg in low-carbon steel, stainless steel, duplex stainless, and high-performance alloys.

• High Precision & Superior Surface Finish: Achieve excellent dimensional accuracy with minimal post-machining, improving productivity and consistency.

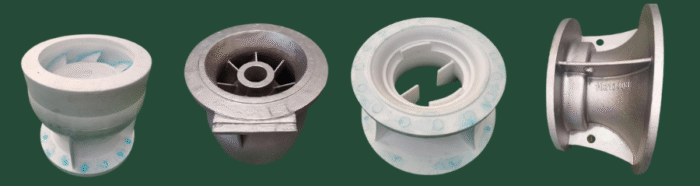

• Complex Geometry Capability: Seamlessly produce guide vanes, bell mouths, pump bodies, impellers, and multi-piece assemblies as single near-net-shape castings.

• Vacuum-Assisted Dimensional Stability:Vacuum flask compaction strengthens shell integrity during pouring and ensures defect-free solidification.

• Reduced Cycle Time: A controlled multi-layer coating process enables cycle times of less than 24 hours from shell preparation to metal pouring.

• No Air conditioning cost for drying of coatings: Lowering energy usage, operational costs and time.

• Low Shell Waste Generation: Minimal shell waste is produced during fettling.

• Eco-Friendly Waste Reuse: Broken shell waste can be ground and repurposed for gardening, landscaping, and other sustainable uses.

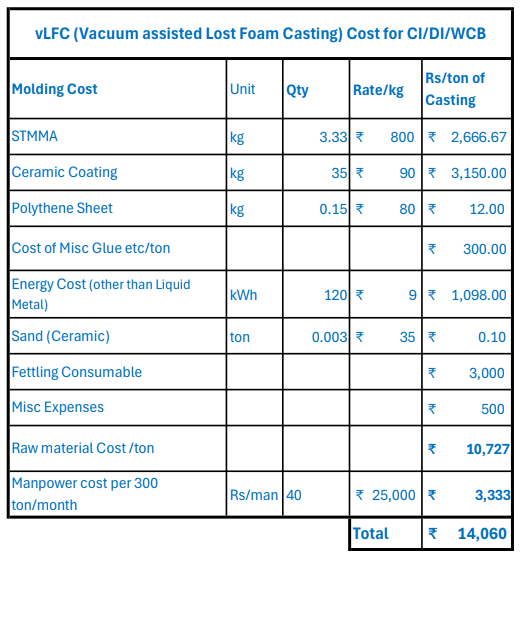

Compared to Lost Wax Investment Casting, the Lost Foam Shell Process can reduce production costs for low-carbon steel castings by approximately 77%. This cost advantage arises primarily because the process requires no air-conditioning, uses less manpower and energy, and delivers a significantly shorter cycle time. Furthermore, when compared to the Replicast process, the Lost Foam Shell Process is even more economical, since no ceramic shell buildup is required.

Download: Comparison Data Sheet

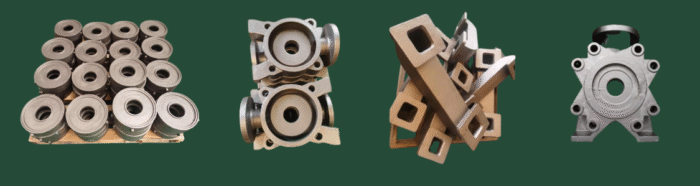

Use the Lost Foam Shell Process for small, medium to large industrial components of low-carbon and stainless-steel castings.

Weight range – Effective for parts from 500g to 2 tons and above; therefore, it suits a wide industrial spectrum from large pump bodies to mid-weight impellers.

1. Water Pump Series – (As-Cast Weight: 375Kg/Set | Casting Material: 2205 duplex stainless steel)

2. Multi-Stage Pump Series Castings – Inlet/Outlet Section, Middle Section, Transition Pipe (Casting Material: 304, 2205/2507 Duplex Stainless Steel)

3. Oil-Free Vacuum Pump Castings – Cylinder Block, Cylinder Head, Cylinder Neck (Casting Material: 304, 316L)

4. Vacuum Pump: Pump Body, Rotor – (Casting Material: 304, 2205, 2507 Duplex Stainless Steel)

Partnering with us for LFS Process Implementation

We implement the Lost Foam Shell Process with full technical support: pattern design, refractory formulation, roasting/gasifier setup, vacuum flask compaction, and pouring methoding. Consequently, we help you scale from prototype to production, reduce rejects, and improve delivery times. For turnkey LFC projects and expert consulting, we train on-site and guide initial production runs to ensure consistent quality.

Ready to adapt the Lost Foam Shell Process for small to large, high-value castings?

Contact us to discuss feasibility, materials, and a cost-saving project roadmap. Email: steel@gdmtechnics.com